PVD Automotive: PVD Coatings for the

Automotive Industry

The Automotive Industry benefits from Physical Vapour Deposition (PVD) for a number of aspects that contribute to the production of modern vehicles for the improvement of efficiency, appearance and optimization of fuel consumption savings.

This article discusses the main areas where automotive design benefits from PVD coatings:

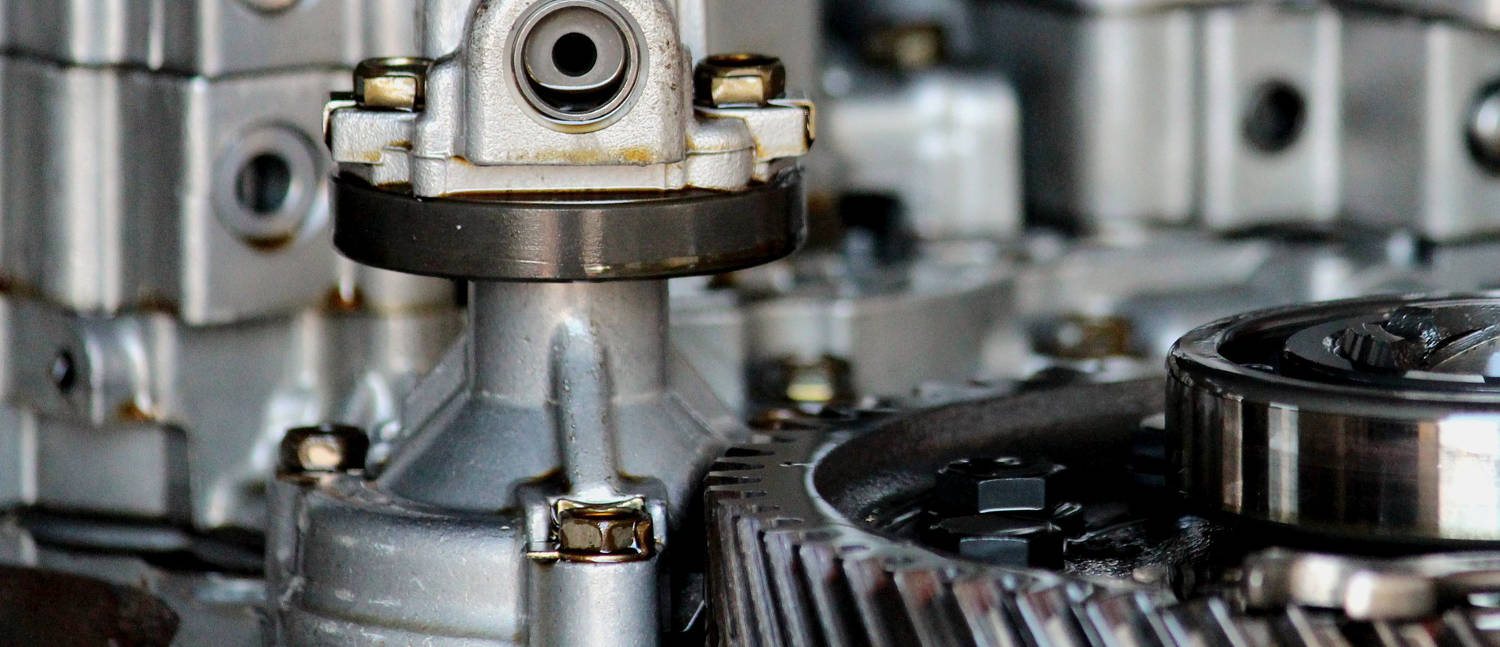

- PVD coating reduces the friction between moving parts in the motor, improving the overall efficiency of the vehicle performance

- Automotive parts with PVD coatings are used to improve the surface hardness, consequently strengthening materials. These choices are made to obtain significant reductions in weight and operating consumption, in both traditional combustion engines and electric motors.

PVD coating reduces friction between moving parts in the motor, improving the overall efficiency of vehicle performance

There are two primary factors that contribute to the reduction of fuel consumption in a vehicle:

- Weight reduction

- Reduction of the friction coefficient of the moving parts

In other words, the lighter the vehicle, the less fuel it consumes to obtain the same performance. The PVD coating allows automotive manufacturers to use lighter alloys for moving parts, such as aluminium, titanium and magnesium, which provide a significant reduction in weight.

Furthermore, the lower the friction between moving parts, the lower the energy consumption. Surfaces treated with some PVD and sputtering techniques have lower friction coefficients for the equivalent lubrication.

It is recognized generally that in an internal combustion engine, the main sources of power loss due to friction are respectively:

- The cylinder bore liner

- The valve train system

- The engine bearings.

In an engine, the valve train is generally responsible for 10% of the power loss due to friction at high speeds, and this percentage is even greater at lower speeds.

For the best performance, over the years valve train components have undergone low-friction PVD coatings to reduce energy losses. The low-friction coating offers a much lower friction coefficient than untreated parts that are lubricated with oil, as well as improving the wear resistance.

The production of automobiles with internal combustion engines is a mature technology that has been active since the beginning of the Nineteenth century. Scientific progress has promoted significant evolution in the technology employed in the industry. Thanks to mass diffusion, this has led to improved performance and lower production costs.

The first automotive components were made from carbon steel or cast iron. Later, to reduce their weight, traditional materials were replaced with lighter alloys, typically aluminium, titanium or magnesium alloys. For example, a few years ago a well-known Japanese manufacturer built a super-charged 804 cc five-valve two-stroke engine that weighed only 85 kg. The block was made from an aluminium alloy. Other components, like the rocker arms, were made from titanium. The weight reduction increased the motor speed by 20%. The problem with these metal alloys is that, while they are tough, their tribological performance is poor. They tend to adhere to the surface against which they rub, causing excessive plastic deformation, abrasive wear and gripping, and consequently high friction.

Friction is the cause of gripping for moving parts, such as valve stems or piston rods. To resolve this problem, light alloy parts are treated with a molybdenum disulfide (MoS2) PVD coating with a low friction coefficient and self-lubricating properties to protect the surface from wear and tear. This lowers the energy loss, improving efficiency, while providing some interesting characteristics:

- Very low friction coefficient (0.05 – 0.1);

- Good hardness (50 HV);

- Excellent oxidation resistance and high heat stability (up to 800 °C)

- Low temperature coating (150 °C);

- Minimum coating thickness (0.5 – 1 μm).

PVD coatings in the automotive industry harden surfaces making them stronger with a significant reduction in weight

PVD and sputtering technologies can be used to obtain results greater than 1000 HV regardless of the low film thickness (1.5 μm), not just theoretical but measurable experimentally with the Vickers hardness test, which evaluates the main characteristics of the coatings.

The progress in the production of mechanical components for automotive engines has been possible due to significant investments in research which are used by racing teams, not just Formula 1 but many other types of races on tracks and roads that aim to bring race car and motorcycle performance to higher and higher levels.

The extreme level of technology experimented in the construction of components, like engine gears and valves, injectors, pistons, cam shafts, engine shafts, piston rings, gudgeon pins, and other mechanical parts studied for racing prototypes is then converted and applied to mass production. This is done when production costs are compatible with the improvement in performance, which is always in the rise even in cars for the consumer market.

Automotive PVD coating finds applications in racing for treating cutting-edge materials like titanium and titanium aluminide alloys, nickel based super alloys with low viscosity flow, NimonicTM and austenitic nickel-chrome based super alloys like InconelTM and even steel valves: these materials can be successfully treated to improve the wear resistance and friction coefficient, decreasing oil consumption and the engine weight.

PVD coating is commonly used in the automotive industry for mass production, including the coating of rims and alloy wheels, for lighting and headlight components, handles, trim and accessories of all types and materials.

PVD finishes improve the appearance of the vehicle, expanding the range of customizations

In the automotive industry, trims play an important commercial role for differentiating models and the manufactures in a market that tends to become flattened on technical characteristics dictated by aerodynamic functions and fashion-influenced aesthetic trends.

In this industry, PVD coated materials provide a real advantage for companies searching for decorative parts for both the interior and exterior with a traditional metal finish, which customers want, with an original, exclusive appearance, but that weigh even less than plastic.

PVD processes allow the coating colours to be customized, as well as the specific gravity, the microstructure and the composite and structural gradient, continuous or multi-layered, based on any specification and with a wide range of colours and metal finishes such as brass, gold, nickel, chrome, copper, bronze, grey, and black, all available with shiny, matt, satin or pearl effect.

Another interesting detail of the automotive PVD process is the wide range of substrates that can be treated with PVD. This ranges from plastic to metal and includes natural materials like wood and fabric. Decorative PVD is often used for interior automotive finishes and the choice of this coating is not limited to the PVD decorative effect to improve the appearance. Its application also improves the solidity and lifetime of these parts, and consequently they have greater corrosion and oxidation resistance.

PVD is more ecological than many other finishing processes. It can be applied without the production of harmful chemical substances or hazardous waste. This is another reason why PVD coatings are rapidly replacing decorative galvanic chrome plate in the automotive industry.

Ask for an estimate for your needs