The most common questions about thin film metal coatings

Here you will find the most common questions and answers about PVD coatings that we have been asked by visitors to our website and that we receive from potential customers who are interested in thin film coatings, suitable for application on all materials where high-performance against wear, corrosion are required, that are biocompatible and with excellent physical and mechanical characteristics.

If you have a question that you do not find here, you are invited to contact us by filling in this form. We will reply in private, and if the question is of general interest, we will publish it on this page.

If you are interested in PVD coatings, galvanic coatings or thin film surface finish coatings in general for the building and industrial, plumbing, tooling, lighting, cosmetic and perfume packaging, gold PVD coating for jewellery or decorative items in general, visit this page often. It is updated regularly!

Questions of PVD coating, thin-film PVD metal coatings: Physical Vapour Deposition and surface finish coatings of materials in general

What is the difference between PVD coating and galvanic coating?

PVD coating can be included among the “physical” metal coating technologies. It can be applied to any surface, not just metals but plastics, improving the appearance and functional characteristics. On the other hand, galvanic coatings are an electrochemical technology that leads to a change in the surface properties of the support, of its corrosion resistance characteristics, the mechanical, electrical, and optical properties.

Can PVD be used to treat semi-finished or finished products, for example, can watches or rifle barrels, pistols or other arms be treated with gold PVD coating?

Yes, PVD coatings can be used to treat semi-finished and finished products, considering that the entire exposed surface is covered.

PVD treatment is ideal for greater tool hardness, such as drill bits, punches, milling heads, as well as screws, nails, bolts and rivets, when an aesthetic finish is required for décor, or for greater brilliance and corrosion resistance of mechanical parts. PVD coating is used also for splendid beautiful effects for jewellery and cosmetics packaging.

What treatments must the surfaces of the supports that are subject to PVD undergo?

To ensure the greatest adhesion of the thin films deposited with PVD, all of the surfaces to be treated must be perfectly clean and there must be no oils or cleaning pastes.

Iron based metals must also be demagnetized and free of any trace of oxidation.

Upon request, the CM Group can provide for the preparation of the parts to be PVD coated with a closed-cycle ultrasound cleaning system, to guarantee the perfect adhesion of the films to any material, shape or condition.

What are the minimum and maximum dimensions of parts that can be subject to PVD coating

The sizes of the parts to undergo PVD coating are evaluated on a case-by-case basis, and generally speaking the maximum dimensions are on the order of 50x100x30 cm. The objects shape is also considered, in order to adapt the support frames, hooks, or other part support systems during the PVD coating, which occurs in a closed chamber.

Is the PVD coating time the same for all metals deposited on all coated supports?

PVD coating time is variable based on multiple factors and can range from a minimum of 90 minutes to a maximum of 180. We value every customer and we carefully study the characteristics of the supports to undergo PVD coating, their shapes, dimensions, weights, and materials they are made from in order to optimize the adjustments of the various phases of the coating, therefore also the overall duration.

What are the delivery times for a standard order for PVD coating?

The CM Group delivery times for PVD coating are always agreed to with the customer during the quotation phase, and the lead time is on average five working days.

Do PVD coating orders have a minimum part limit? Can trial samples be performed?

PVD coating orders do not have a minimum part limit, and can even be lots of just a few parts.

Upon request, sampling and coating trials can be performed. We place our 30 years of experience and the high-technology tools that we use for the quality control of our processes at the service of our customers with the objective of obtaining the best finish results under any condition.

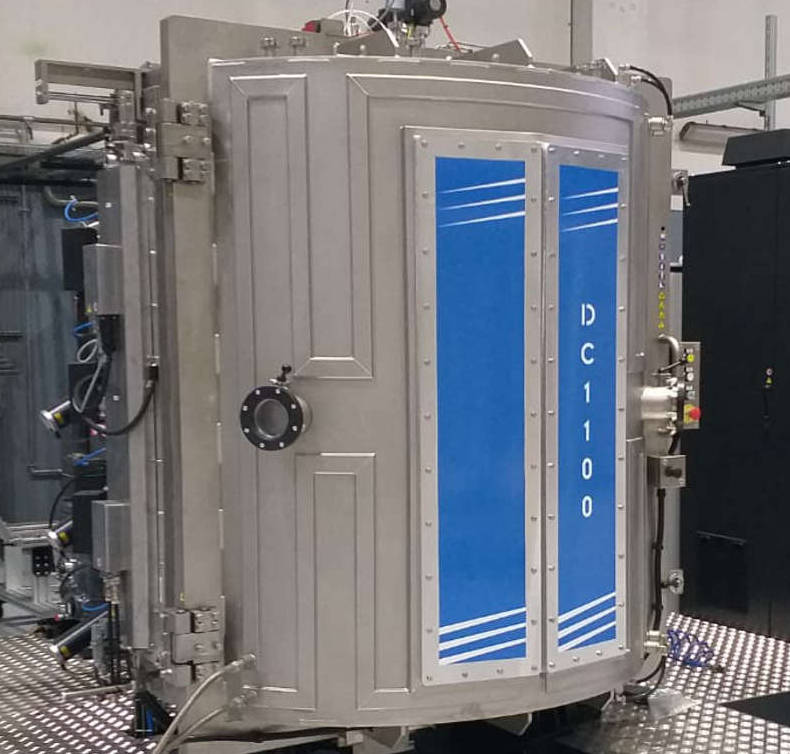

In our Vobarno plant, in the Province of Brescia, we have installed a new system for PVD thin-film metal coatings: Physical Vapour Deposition.

In our Vobarno plant, in the Province of Brescia, we have installed a new system for PVD thin-film metal coatings: Physical Vapour Deposition.

Why should we install a new PVD coating line if we have another that is fully functional?

The new PVD thin-film metal coating line allows us to add new finishes to our product range, with new colours and different technologies. Furthermore, this important investment allows us to optimize processes, guaranteeing faster delivery times and more competitive services, both for better performance of the system, and because the most modern technology allows for an improvement of the entire production cycle.

Ask for an estimate for your needs